Brushless DC (BLDC) Motor Driver / Controller

Motor Driver / Controller is used to control the motion of a motor and its direction by feeding current accordingly. The output of a motor driver is in digital form so it uses PWM (Pulse Width Modulation) to control the speed of a motor. Motor Drivers are basically current amplifiers followed by input signals. It can also drive inductive loads such as relays, solenoids, transformers, etc.

Block Diagram of Motor Driver

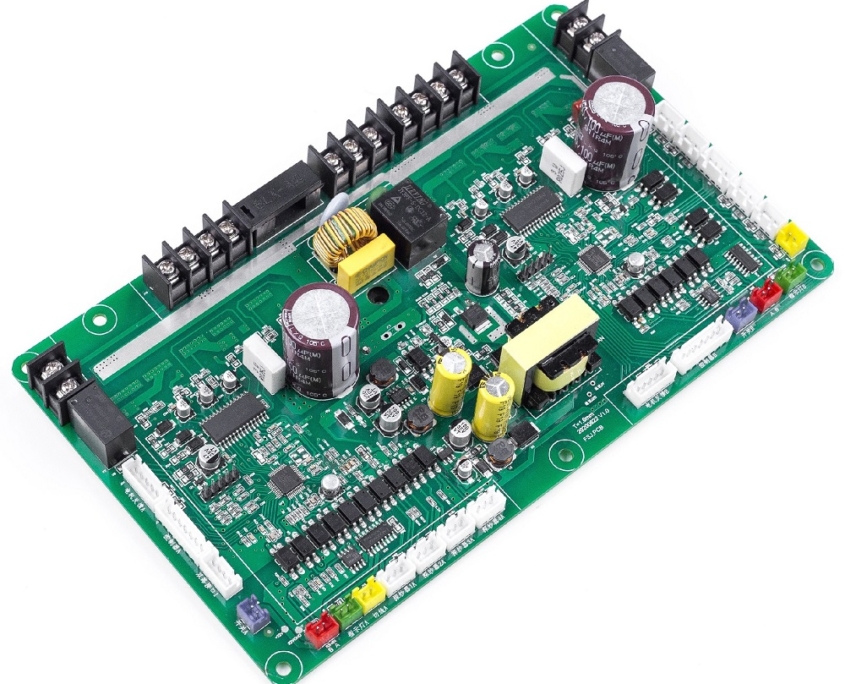

PCB of Motor Controller / Driver from Ningbo Etg Tech Ltd

Types of DC Driver / Controller

DC motor drives are classified based on the type of DC motor being used. These types include brushed, brushless, servo, linear, and voice coil motors.

Brushed motors commutate via physical contacts, often spring-loaded graphite brushes biased against the commutation bar.

Brushless motors commutate electronically with no physical brush contact. One common technique for positional feedback to control commutation is the use of Hall effect sensors to detect rotor position. Commutation options include trapezoidal and sinusoidal drive signals to the motor.

Servomotors can be of the brush or brushless design and include an internal sensor for position control and other industrial automation applications. If brushless, the commutation of the three phases will typically be either trapezoidal or sinusoidal; the term “DC brushless” often connotes the trapezoidal commutation of a brushless motor with Hall Effect sensor feedback for commutation control.

Linear motors generate force only in the direction of travel. The motor technology resembles rotary motor technologies simply oriented in a linear fashion. Linear motors are capable of extremely high speeds, quick acceleration, and accurate positioning. Linear motor technologies include moving coil, moving magnet, AC switched reluctance design, AC synchronous design, AC induction or traction design, linear stepping design, DC brushed design, and DC brushless design.

Voice coil motors consist of a magnetic coil placed in a magnetic field. When current is applied to the coil, electromagnetic flux is generated which causes the coil to move. The motor’s name is derived from its resemblance to audio speaker operation.

DC motor drives can also be classified based on types of control functions (e.g. integral motion controllers, variable speed drives, motor speed controllers, etc.).

Performance Specifications

There is a wide range of operating specifications to consider when searching for DC motor drives. The most important of these include:

- Continuous current – the current applied to the motor during continuous operation.

- Input frequency – the AC input frequency accepted by the device.

- Power – the rated power output of the drive motor system.

- Supply voltage – the voltage supplied to the drive.

- Operating temperature – the operating temperature of the power supply.

Other important characteristics include the mounting configuration and accompanying features.

Mounting Configuration

Drive mounting configuration is important for compatibility with the motor system. Drives can be mounted in various ways based on the design, including onto a PCB (printed circuit board), PC board, panel, DIN rail, or rack. Other drives may be stand-alone devices or designed to be incorporated into specific products by original equipment manufacturers (OEMs).

Features

DC motor drivers may also include various features which may be important for certain applications. These include:

- Regeneration – Method of braking in which the motor is disconnected from the power supply and power generated from the rotating motor is sent back to the supply.

- Programmability and configuration – The device can be programmed with routine configurations and commands for greater functionality and process control.

- Auto restart – Drive is designed to automatically restart operation after a stall.