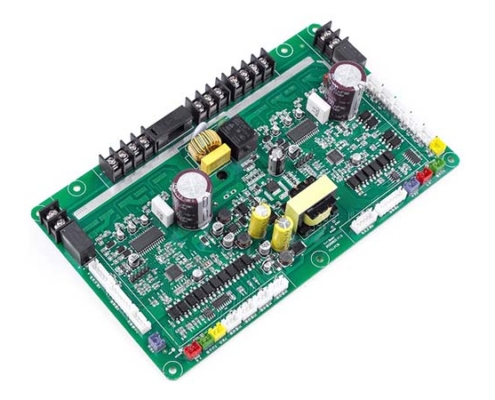

300W PMSM Driver/Controller

Three-phase PMSM (Permanent Magnet Synchronous Motor) driver / controller board. The driver / controller is a DC motor drive for the winding machine in the textile machinery industry. Because it is based on the field-oriented control (FOC) or vector control method, the control is more precise, and it provides a pixel-level control solution for the winding machine. Less noise and softer winding.

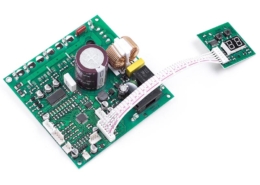

This product can drive two motors at the same time. At the same time, the system integrates the spinning length measurement, yarn breakage detection, pulse detection and other functions required by the winder.

Integrated with RS485 communication, the control is more flexible, and it can be connected to the host computer for centralized control.

| Product Series | LSMD0300WA |

| Driveable Motor Power | 300W |

| Driveable Motors | 2 PCS |

| Input Voltage | Single Phase 220VAC |

| Input Current | 5A |

| Algorithm Control | FOC field-oriented control/position control |

Features

- Faster winding speed: In the actual working process of this driver, the rated line speed is 600m/min, and the maximum line speed reaches 800m/min.

- More energy-saving: The motors controlled by this control system are permanent magnet DC brushless motors, and at the same time, the separation of mechanical structures is effectively realized, so as to better achieve a significant reduction in energy consumption.

- The steady-state speed control error of the control system for brushless DC motors reaches 0.1%;

- The winding system is effectively separated from the yarn guiding system, enabling yarn winding with different winding ratios;

- Stable, precise, and non-overshoot line speed control performance and provide more flexible and rich line speed control modes. The system has built-in single-segment linear speed mode, two-segment linear speed mode, linear speed decreasing mode, and linear speed increasing mode;

- Humanized intelligent control performance, the system has a built-in intelligent yarn length counting function, intelligent dynamic stability function of line speed, overfeeding system self-tuning and synchronous tracking, and other intelligent functions, which further simplifies the difficulty of system debugging parameter setting and greatly improves system self-efficacy. adaptability.

- Build-in full Protection; Overvoltage Protection; Lose-of-load(undercurrent) Protection; Overload(yarn) Protection; Overheating Protection; Noload(yarn) Protection; Wrong Input Protection; Communication Failure Protection; External Data Failure Protection…

Control Mode

- Winding motor frequency control: Control the winding motor target frequency, fundamental frequency, swing frequency amplitude, and swing frequency times;

- Winding motor line speed control: Built-in line speed operation mode;

- Winding motor constant tension control: Set winding motor tension control parameters;

- Yarn guide motor control: Control the running mode, speed, running direction, etc. of the yarn guiding motor

Environment

- Place of use: No corrosive gas, No conductive dust, Well-ventilated indoors

- Ambient Temperature: -20℃-45℃

- Relative Humidity: relative humidity below 90%, no condensation

- Vibration: Vibration below 0.5G

- Altitude: Below 1000 meters

Ningbo Etg Tech Ltd

Ningbo Etg Tech Ltd Ningbo Etg Tech Ltd

Ningbo Etg Tech Ltd Ningbo Etg Tech Ltd

Ningbo Etg Tech Ltd Ningbo Etg Tech Ltd

Ningbo Etg Tech Ltd Ningbo Etg Tech Ltd

Ningbo Etg Tech Ltd Ningbo Etg Tech Ltd

Ningbo Etg Tech Ltd Ningbo Etg Tech Ltd

Ningbo Etg Tech Ltd Ningbo Etg Tech Ltd

Ningbo Etg Tech Ltd Ningbo Etg Tech Ltd

Ningbo Etg Tech Ltd